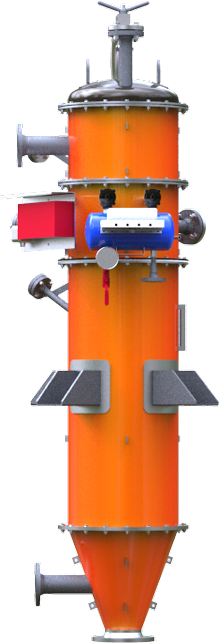

INFA-MINI-JET AJM

Bag filter in circular design

Highlights

The bag filter series INFA-MINI-JET is a versatile circular filter program. Customer-specific designs are available due to individual constructions. Because of an optional hot gas design, pressure resistance and gas-tightness, the fully automated filters ensure the separation of dust and powder products as well from exhaust air as from process gases.

During the filtration phase the cleaning of the filter bags is done in periodic intervals by pulses of compressed air (jet-pulse cleaning). The filter sizes cover a volume flow of 20 m³/h to 9,000 m³/h.

Standard design features

- asic module consisting of

- closed filter head

- filter elements and

- pneumatic cleaning unit

- Expandable modular system for flexible adaptation to specific applications

- Housing strength up to +/- 50 mbar g

- Up to 80 °C

- System can be equipped either with filter cartridges or filter bags

- Easy filter media change from the clean gas side with quick clamp fastening

- Design as

- Top filter

- Insert filter

- Standing filter (dedusting unit)

Options

- Modular supplements and accessories, e. g.

- filter housing

- hopper and dust bin

- level indicator within the dust bin

- butterfly valve

- rotary valve

- fan

- inspection cover

- secondary filter stage

- All housing parts, internal parts or components in contact with the product / dust made of stainless steel

- Housing strength up to +/- 0.5 bar g for pressure- or vacuum-pneumatic operation

- Design for ATEX zones according to directive 2014/34/EU (ATEX)

- Pressure shock resistant design up to 26 barg

- Electronic control unit for filter cleaning controlled by timing cycle or differential pressure. Also for additional components (fan, rotary valve, etc.)

- Control system and motors for special voltages, e.g. 500 V

- Design for hot gases up to 240 °C

- Filter media available in different qualities, e.g. according to guideline EU 1935/2005 and EU 10/2011 for food industry

- Sound absorbing kits for use in noise-sensitive environments

- Exchange of filters elements on the raw gas side if not enough space in height is available

- Electric heating of the filter housing including thermal insulation

- Slewing mechanism for inspection cover on the clean gas side

| Filter type | Filter surface[m²] | Compressed air consumption* [Nm³/h] | Dimension sheet |

|---|---|---|---|

| 500-300-0,6 S | 0,6 | 7 | 6010 |

| 500-550-1 S | 1,1 | 7 | 6010 / dsf 6020 |

| 500-1100-2 S | 2,2 | 7 | 6010 / dsf 6020 |

| 710-550-2 S | 2 | 9 | 6010 |

| 710-1100-4 S | 4 | 9 | 6010 / dsf 6020 |

| 900-550-3 S | 3,5 | 9 | 6010 |

| 900-1100-7 S | 7 | 9 | 6010 / dsf 6020 |

| 1100-1100-11 S | 11 | 9 | 6010 / dsf 6020 |

| 1100-1600-15 S | 15 | 9 | 6010 |

| 1400-1100-17 S | 17 | 9 | 6010 / dsf 6020 |

| 1400-1600-24 S | 24 | 9 | 6010 |

*6 bar at 10 sec. pause

dsf = pressure shock resistant