Cement, lime, gypsum

It’s a long way from the stone quarry to the concrete mixer. A significant amount of dust is produced during the different work processes. This amount must be reduced and removed by modern filters.

Dust extraction solutions from Infastaub reduce the dust emissions in a number of places during the production process.

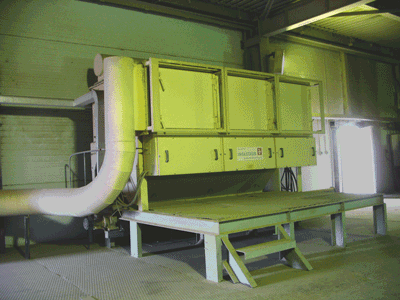

Filter units for building materials plant

A building materials plant was modernised and equipped with 15 dedusting units of Infastaub. They serve to dedust 26 dust sources (elevators, crusher, sieves, scale bunker, belt transfer points, packing machines, pneumatic conveying etc.).

Overall the 15 filter units de-dust a total volume flow of > 40,000 m³/h. The different filter units gather, e.g. as silo vent filter (AJB, AJV) or central dedusting plant (AJL), at different dust sources the dust emissions of gypsum, marble meal, ash, cement and quartz sand. Particular attention on the residual dust content of < 0.5 mg/m³ was paid to the de-dusting of a cement-sand-mixture. For this application a cassette filter type Infa-Micron MKR with non-cleanable secondary filter stage was installed downstream of a pleated element filter.

The air volume of several, synchronal working processes with same dusts are combined in one filter unit in order to keep the total amount of filter units as low as possible. The filter units for plants as scale bunkers and dosing feeder should have a differential pressure as much low as possible and without fluctuations. This is designed with regard to a proper operation of the pressure instruments of the conveying aggregates.

| Technical data | ||

|---|---|---|

| Filter typs | Silo filter Infa-Jetron AJB | |

| Volume flow | [m³/h] | in total approx. 40.000 |