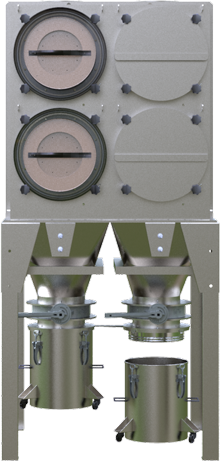

INFA-MICRON MPR

Cartridge filter for dedusting of sophisticated processes where toxic dusts or powders, e.g. API (Active Pharmaceutical Ingredients)

Highlights

The cartridge filter INFA-MICRON MPR was especially developed for dust which are high potentially dangerous and also are filtration-technically demanding. Its horizontally inserted filter cartridges are cleaned by a jet pulse system, supported by a special injector and upper area regeneration of the cartridge (offline). This method allows the separation also with adhesive or sticking dusts, because the jet pulse cleaning brings in higher cleaning energy into the filter cartridges than the backflush system of cassette filters. In addition, the filter cartridges can be precoated or operated with a continuous additive supply. The cleanability is thereby preserved on a long-term.

The MPR cartridge filter is a user-friendly and high efficient dedusting unit. Efficiency of this filter series covers a wide range of filtration duties in pharmaceutical, chemical, metallurgical and nuclear-technical industry. The processes in these industrial branches are very demanding on dust separation efficiency. Infastaub offers suitable handling systems according to requirements of contamination protection. Like the cassette filter MKR the maintenance staff can carry out the dust disposal and the change of filter media free of contamination (up to OEB 4 | 1-10 µg/m³) with the help of the "Safe-Change" system.

Standard design features

- Cleanable cartridge filter in modular design with one or two filter stages with horizontally arranged filter cartridges

- Standard +/- 50 mbar and up to 80 °C, optional 250 mbar and 150 °C

- Pressure shock resistant up to 1.0 barg and Kst = 300 bar m/s possible

- Filter housing made of mild steel S235JR with hopper and dust discharge system respectively dust collection equipment

- Spring supported pneumatic fastening of filter cartridges on the clean gas side for easy filter change and permanent safe tightening between raw and clean gas area and to exterior ambience

- Increased safety because of filter cartridges sealed to the outside, which are an additional barrier within containment philosophy

- High efficient jet pulse cleaning system with Coanda injector for filter cartridges of 1st stage

- Raw gas dust load up to 10 g/m³

- Modular system for flexible adaption to individual requirements, suitable up to +80 ºC

- Electronic, programmed control unit for filter cleaning triggered by time cycle or differential pressure incl. Coanda injector and shut-off valve, monitoring of single operating conditions by proximity switches and indication by plain-text display

- Minimum shutdown time as well as low operating and maintenance costs because of high reliability and easy handling

Options

- 2nd filter stage (not cleanable) as safety filter respectively "back-up filter" with filter media according to DIN EN 1822

- Filter media in different qualtities and classes up to H14 according to DIN EN 1822

- "Safe-Change" system for change of dust collection bin and filter cartridges free of contamination up to OEB 4

- Dust discharge by liner or endless bag system

- Dust discharge by pneumatic conveying into central barrel with "Safe-Change" system

- Adaptability for customized dust collecting barrel

- Explosion protected design according to directive 2014/34/EU (ATEX)

- Pressure-shock resistant design for reduced explosion pressure up to 1.0 barg without additional, cost expensive relieve devices for dusts of explosion class up to St2

- Gas tight welded and strengthened filter housing for pressures up to +/- 250 mbar

- Housing parts and internal parts made of stainless steel

- Filter control as PLC with any special function and interface to master process control system

- Electric heating of filter housing including thermal insulation

- Control system and motors for special voltages, e.g. 500 V

- Connections for DOP tests of 1st and 2nd filter stage

- Precoating or continuous additive supply for better cleanability of filter cartridges while operating with adhesive or sticky dusts

- Various accessories , e.g.

- Shut-off valve and dust collecting bin at dust discharge

- Level indicator within the dust bin

- Fan

- Contact sensors for locking of dust collecting bin, inspection cover and shut-off valve's blade position

- Lift cart for a safe change of dust bin

- Mobile service help for change of filter cartridges

| Filter type | Filter surface[m²] | Compressed air consumption* [Nm³/h] | Dimension sheet |

|---|---|---|---|

| 1/20-1/20 | 20 / 20** | < 5 | on request |

| 2/20-2/20 | 40 / 40** | < 5 | on request |

| 3/20-3/20 | 60 / 60** | < 5 | on request |

| 4/20-4/20 | 80 / 80** | < 5 | on request |

| 5/20-5/20 | 100 / 100** | < 5 | on request |

*6 bar at 10 sek. pause

**Filter surface 1. filter stage / Filter surface 2. filter stage