Explosionsschutz

Explosions can only occur in case of certain conditions. This includes the simultaneous occurrence of

- flammable substance with small particle size (e.g. flammable dust) being dispersed in air

- sufficient concentration of the flammable dust

- an effective ignition source

In this case, a fast elapsing combustion reaction with flames and pressure effects is possile. This is commonly known as an explosion. If only one of the above mentioned conditions can surely be excluded, the occurrence of an explosion isn't possible anymore. In this case, this is so-called preventive explosion protection, aiming to prevent explosions in process-related systems.

Explosion protection terminology definitions

- Explosion: A sudden oxidation reaction (combustion reaction) with a rise in temperature, pressure or both simultaneously. [1]

- Dust: Fine-particulate solid matter of any shape and density below a particle size of 500 µm.

- Median value: Median particle size of the dust, 50 wt% being smaller and 50 wt% being larger than the median value.

- Explosive atmosphere: A mixture of air and flammable gases, vapours, mists or dusts under atmospheric conditions in which a combustion reaction spreads to the entire unburned mixture after the mixture has been ignited. [1]

- Zone classification: Potentially explosive areas are divided into zones in accordance with the frequency and duration of the occurrence of a hazardous explosive atmosphere. This classification is used as the basis for defining explosion protection measures.

- Effective ignition source: An ignition source that can ignite an explosive atmosphere. Examples of effective ignition sources are hot surfaces, mechanically generated sparks, electrical equipment, static electricity and lightning strikes. See [2] for a complete overview of all ignition sources.

- Preventive explosion protection: An explosion protection concept with the aim of reliably preventing explosions, e.g., by avoiding explosive atmospheres and/or avoiding effective ignition sources.

- Constructional explosion protection: An explosion protection concept with the aim of controlling the effects of explosions by means of technical measures. This includes explosion-proof design in conjunction with explosion decoupling.

- Safety parameters: Safety parameters describe the safety-related properties of flammable substances. Safety parameters are not constants, but rather they depend on various influences, such as the particle size distribution, the particle shape, the moisture content and the presence of additives. [2]

Safety parameters of constructional explosion protection

Max. explosion overpressure (Pmax):

The highest explosion overpressure that can occur in a closed container, independent of the concentration of the fuel.

Kst value:

The highest rate of pressure rise of an explosion that can occur in a closed 1m³ container, independent of the concentration of the flammable dust.

Hybrid mixture:

A mixture of simultaneously occurring flammable dusts and flammable gases in air. Mixtures are referred to as hybrid mixtures if gas concentrations ≥ 20% of the UEL occur or if dusts with solvent contents ≥ 0.5 wt% are present. Hybrid mixtures can result in additional explosion hazards.

Safety parameters of preventive explosion protection

- Upper and lower explosive limits: The upper explosive limit (UEL) and lower explosive limit (LEL) are the upper and lower concentrations of a flammable substance in air at which a flame independent of the ignition source can no longer propagate independently after ignition. [1] Unlike with gases, there is no real upper explosive limit for dusts, because even at high dust concentrations, part of the dust can react with the air present, and the concentration of the dust in a dust cloud can differ locally to a large extent. Therefore, only the LEL is generally determined for dusts.

- Minimum ignition energy (MIE): The lowest amount of electrical energy stored in a capacitor that is sufficient to ignite the most readily ignitable mixture of an explosive atmosphere when the capacitor is discharged.

- Smouldering temperature: The lowest temperature of a hot surface that ignites a dust layer on it of 5 mm thickness.

- Ignition temperature: The lowest temperature of a hot surface on which the most readily ignitable dust/air mixture (dust cloud) ignites.

- Resistivity: The electrical resistivity of the dust.

Quellen: [1] BGR 104 - Explosionsschutz-Regeln (EX-RL) www.bgrci.de/exinfode/ex-schutz-wissen/expertenwissen/brennbare-staeube/2-umsetzung-der-explosionsschutz-regeln-ex-rl-bgr-104/ [2] DIN EN 1127-1 - Explosionsfähige Atmosphären - Explosionsschutz - Teil 1: Grundlagen und Methodik

Constructive explosion protection

It is not possible in all cases to reduce the risk of an explosion to the required level only by selecting suitable equipment. In addition to the primary safety measures, such as avoiding ignitable mixtures or removing their tendency to explode by rendering them inert, it is also necessary for components to have an explosion-proof design in order to limit the effects of an explosion and to eliminate the risk of injury to people.

- Absolute relief area: Total effective relief area provided on a container.

- Container volume: Empty volume that must be used as the basis for sizing the pressure relief areas.

- Bursting discs for dust removal systems: Round or rectangular stainless steel discs clamped between two flanges. Bursting discs are provided with predetermined breaking points at the clamping end and sealed by a sealing membrane. If the explosion pressure exceeds the burst pressure, the predetermined breaking points tear and the relief opening is released.

- Pressure relief: Protection principle whereby the explosion pressure is limited by expelling unburned mixture and combustion gases by releasing predetermined openings, thereby avoiding the destruction of the equipment.

- Pressure-resistant containers: Containers and apparatuses that are constructed as pressure vessels in accordance with the applicable regulations and directives.

- Pressure-shock-resistant containers, apparatuses and associated pipelines that are constructed in such a way that they withstand the pressure shock occurring during an explosion up to a certain magnitude without bursting; however, permanent deformation can occur. The pressure shock resistance is used as the basis for performing calculations for pressure-shock-resistant containers.

- Relief pressure: Maximum expected pressure during an explosion in a pressure-relieved space or in a pressure-relieved apparatus.

- Relief area: Total effective relief area provided on a container, which can comprise several partial areas. Non-bursting vacuum supports and other components that obstruct the mass flow must be taken into account.

- Maximum explosion pressure: The "maximum explosion pressure" pmax refers to the highest pressure that can occur during an explosion of a fuel/air mixture of optimal concentration in the closed container or apparatus.

- Explosion doors: Safety devices that are opened by the explosion pressure. In contrast to bursting discs, explosion doors can automatically close the blow-out openings again after having been activated. For explosion doors, it is not the actual opening but rather the relief area determined by the expert during type testing that must be used as the basis.

- Preliminary pressure: Initial pressure present when the ignition source becomes effective

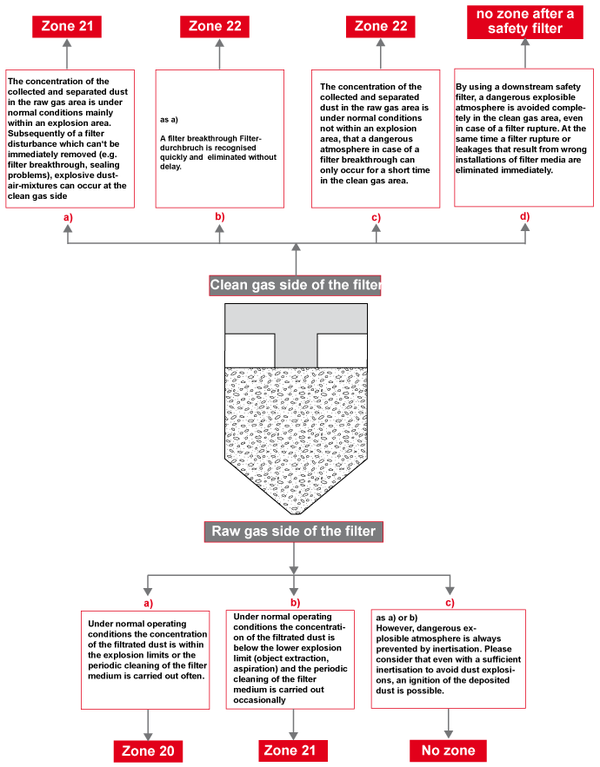

Zone classification in a bag filter

Source: [3] BGR 104 - Explosionsschutz-Regeln (EX-RL), EX-Tabelle - Punkt3 Brennbare Stäube, www.bgrci.de/exinfode/dokumente/explosionsschutz-regeln-bgr-104/