Glass, ceramic industry

In the first place, dust emissions occur during batch creation or provision for the melting process and during glass processing. That is why glassworks have to implement an environmentally acceptable production process complying with legal emission targets. Glass-specific dust emissions can be removed from exhaust air using fabric filters.

When manufacturing ceramic products measures against dust have to be taken as well. Infastaub supplies a wide range of filter sizes, designs and constructive solutions for these fields of business.

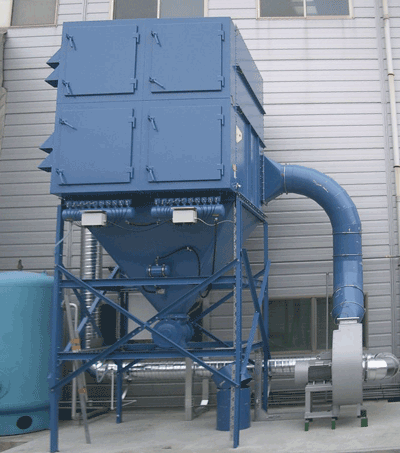

Pocket filter for dedusting of a new glass production

In a batch plant the required raw materials for glass production are stored in silos, from there charged into container scales and weighed according to the later glass composition. Afterwards the raw materials are mixed and transported to the glass melter via conveyor belts or buckets.

In a new glass factory for bottle glass in Mexico is equipped the production and transport processes are dedusted with 24 pocket filters of series INFA-JET AJN. The volume flows amount to 60 - 1,500 m³/h with a filter area of 1 - 45 m². The demanded clean gas dust contents are about < 10 mg/m³.

| Technical data | ||

|---|---|---|

| Filter type | Pocket filter Infa-Jet AJN | |

| Volume flow | [m³/h] | 60 - 1,500 |

| Raw gas dust content | [g/m³] | 1 - 10 |

| Clean gas dust content | [mg/m³] | < 10 |

| Filter area per filter | [m²] | 1 - 45 |