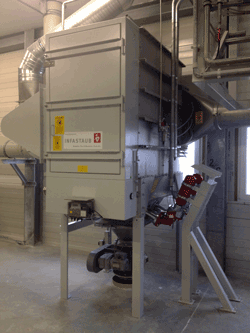

Pleated element filter for dedusting of special chemicals needed by plastics industry

For dedusting the manufacturing process of special chemicals an aspiration filter of type Infa-Lamellen-Jet is used. In spite of small floor space a filter surface of 72 m² could be realised because of the optimised filter geometry.

The requirements for the new filter unit were very special. The paraffin containing dust particles are adhesive and waxy. Therefore pleated elements with a laminated PTFE membrane are used. The diaphragm allows a stable dust removal process. Furthermore this dust kind is potentially explosive. The pleated element filter was therefore designed pressure shock resistant up to 0.4 bar g and equipped with an explosion suppression system. Additional explosion decoupling systems on the raw gas and clean gas side were planned by the customer.

| Technical data | ||

|---|---|---|

| Filter type | Pleated element filter Infa-Lamellen-Jet AJL | |

| Dust kind | paraffinic | |

| Filter area | [m²] | 72 |

| Filter material | PTFE membrane | |