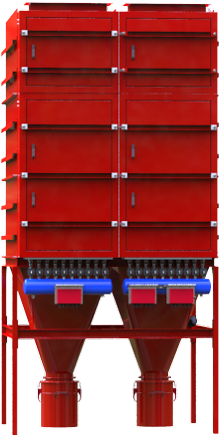

INFA-JET AJN

Pocket filter with pneumatic jet-pulse cleaning for continous dedusting of machines and work places

Highlights

The pocket filter system INFA-JET is a flexible modular system for continuous de-dusting of machines and workplaces.

The extensive series is suitable for volume flows of approx. 100 m³/h to approx. 25,000 m³/h. Almost every combination of design - high, low, round or rectangular - is practicable. During the filtration phase, the cleaning of the filter pockets or pleated filter elements is done in periodic intervals by pulses of compressed air (jet cleaning).

Almost every customer demand can be fulfilled with the pocket filter INFA-JET type AJN - we realise for you the most economical solution both within requirements of the process technology as well as in case of difficult spatial situations. For example:

- as vent filter with or without filter housing or with secondary filter stage

- without or with adjacent or flanged fan

- with dust discharge via rotary valve, double pendulum flap or dust bin

- in pressure shock resistant design respectively with constructive explosion protection

- variants with one chamber or multiple chambers

Standard design features

- Basic module consisting of closed filter head, filter elements and pneumatic cleaning unit

- Housing strength up to +/- 50 mbar g (basic version), up to 80 °C

- Eckige Ausführung bis +/-0,4 bar druckstoßfest

- Runde Ausführung von 0,5 bar bis 3 barÜ druckstoßfest

- Design as

- standing filter (dedusting device)

- top filter

- insert filter

- Modular system for flexible adaption to each application

Options

- Modular supplements, e.g.

- filter housing for horizontal or vertical pocket arrangement

- lower section with hopper, supporting legs and dust collecting bin

- design as cylindrical dust collector (“total separator”)

- flange-mounted or console-mounted fan

- inspection cover

- secondary filter stage

- Various accessories at dust discharge, e.g.

- butterfly valve

- rotary valve

- double pendulum flap

- screw conveyor

- level indicator within the dust bin

- Pressure-resistant design for process pressures above and below atmosphere up to +/ 0.5 bar g

- Pressure-shock resistant design for reduced explosion pressure (e.g. 0.4 bar g or 2.0 bar g) with pressure relief or for maximum explosion pressure (9 bar g)

- Electronic control unit for filter cleaning controlled by timing cycle or differential pressure. Also for additional components (fan, rotary valve, etc.)

- Control system and motors for special voltages, e.g. 500 V

- All housing parts, internal parts or components in contact with the product / dust made of stainless steel

- Filter media available in different qualities (e.g. FDA-conform for food industry)

- Design for hot gases up to 240 °C

- Sound absorbing kits for use in noise-sensitive environments

- Electric heating of the filter housing including thermal insulation

- Quick-exchange technology for easier access in case of filter media change

- Design for ATEX zones according to directive 2014/34/EU (ATEX)

| Filter type | Filter surface[m²] | Compressed air consumption* [Nm³/h] | Dimension sheet |

|---|---|---|---|

| 043 FH | 4 | 7 | 3031 |

| 063 FH/UT | 6 | 7 | 3031/3030 |

| 083 FH/UT | 8 | 7 | 30313030 |

| 103 FH/UT | 10 | 7 | 30313030 |

| 1/103 Q | 7 | 3030 | |

| 123 FH/UT | 12 | 7 | 30313030 |

| 153 UT | 15 | 7 | 3030 |

| 1/153 | 15 | 7 | 3032 |

| 1/153 QSL | 15 | 7 | |

| 203 UT | 20 | 7 | 3030 |

| 1/203 | 20 | 7 | 3032 |

| 2/103Q | 20 | 14 | |

| 1/303 SL | 30 | 7 | 3032 |

| 1/303 | 30 | 9 | 3032A |

| 2/153 | 30 | 14 | 3032 |

| 2/153 QSL | 30 | 14 | |

| 3/103 Q | 30 | 21 | |

| 1/403 | 40 | 9 | 3032B |

| 2/203 | 40 | 14 | 3032 |

| 1/453 SL | 45 | 9 | 3032A |

| 3/153 | 45 | 21 | (3032) |

| 3/153 QSL | 45 | 21 | |

| 2/303 SL | 60 | 14 | 3032 |

| 2/303 | 60 | 18 | 3032A |

| 3/203 | 60 | 21 | 3032 |

| 4/153 | 60 | 28 | |

| 1/603 SL | 60 | 9 | 3032B |

| 5/153 | 75 | 35 | |

| 2/403 | 80 | 18 | 3032B |

| 4/203 | 80 | 28 | (3032) |

| 3/303 SL | 90 | 21 | 3032 |

| 2/453 SL | 90 | 18 | 3032A |

| 3/303 | 90 | 27 | 3032A |

| 5/203 | 100 | 35 | (3032) |

| 4/303 SL | 120 | 28 | (3032) |

| 2/603 SL | 120 | 18 | 3032B |

| 3/403 | 120 | 27 | 3032B |

| 4/303 | 120 | 36 | (3032A) |

| 3/453 SL | 135 | 27 | 3032A |

| 5/303 | 150 | 45 | (3032A) |

| 5/303 SL | 150 | 35 | (3032) |

| 4/403 | 160 | 36 | (3032B) |

| 4/453 SL | 180 | 36 | (3032A) |

| 3/603 SL | 180 | 27 | 3032B |

| 5/403 | 200 | 45 | 3032B |

| 5/453 SL | 225 | 45 | (3032A) |

| 4/603 SL | 240 | 36 | (3032B) |

| 5/603 SL | 300 | 45 | (3032B) |

| x/xxx (SL) | 3033 | ||

| 03_ | 3 | 7 | 3010-3017, 3020-3027 |

| 04_ | 4 | 7 | 3010-3017, 3020-3027 |

| 06_SL | 6 | 7 | 3010-3017, 3020-3027 |

| 06_ | 6 | 7 | 3010-3017, 3020-3027 |

| 08_ | 8 | 7 | 3010-3017, 3020-3027 |

| 10_ | 10 | 7 | 3010-3017, 3020-3027 |

| 10_Q | 10 | 7 | 3010-3017, 3020-3027 |

| 12_SL | 12 | 7 | 3010-3017, 3020-3027 |

| 12_ | 12 | 7 | 3010-3017, 3020-3027 |

| 15_ | 15 | 7 | 3010-3017, 3020-3027 |

| 15_Q, SL | 15 | 7 | 3010-3017, 3020-3027 |

| 18_SL | 18 | 7 | 3010-3017, 3020-3027 |

| 20_ | 20 | 7 | 3010-3017, 3020-3027 |

| 23_ | 23 | 9 | 3010A-3017A, 3024A-3027A |

| 30_ | 30 | 9 | 3010A-3017A, 3024A-3027A |

| 30_SL | 30 | 7 | 3010-3023 |

| 40_ | 40 | 9 | 3010A-3017A, 3024A-3027A |

| 45_SL | 45 | 9 | 3010A-3017A, 3024A-3027A |

| 60_SL | 60 | 9 | 3010A-3017A, 3024A-3027A |

*6 bar at 10 sec. pause