General information

- Type of system, process, device or machine

- Mode of operation of the filter system (continuous or intermittent)

- Gas properties (e.g., hazardous to health, flammable or corrosive)

- Particle properties (e.g., hazardous to health, flammable, hygroscopic, sticky or agglomerating)

- Gas/dust mixture properties (e.g. explosive)

Design checklist

- Height above sea level in m

- Data on gas being cleaned

- Flow rate in m³/h

- Temperature in °C

- Composition (e.g., volume fractions)

- Humidity in g/kg dry air

- Water dew point (acid dew point, if necessary) in °C

- Density in kg/m³

- Gas pressure when entering separator in hPa

- Desired clean-gas dust concentration in mg/m³

- Data on particles

- Average concentration in raw gas in g/m³

- Maximum concentration in raw gas in g/m³

- Particle size distribution

- Density in g/cm³

- Bulk density in g/cm³ or t/m³

- Composition by material constituent in relation to dry substance in % by weight

- Water content in relation to dry substance in % by weight

Volume flow (Q)

The basis for the design of filtering separators is knowledge of the flow rate being cleaned. This either depends on the process or on extraction conditions (e.g., dust protection at the workstation)

Important factors are:

- Temperature

- Pressure

- Gas atmosphere

- Properties of dust material being separated and its concentration

A starting point for determining air flow rates is the capture velocity at open surfaces, inlets, hoods and machine coverings

Q [m³/min] = A [m²] x v [m/s] x 60

| Emission | e. g. | capture velocity [m/s] |

|---|---|---|

| static | degreasing/galvanic bath, smock | 0.25 - 0.5 |

| slow | filling, welding, slow conveyor transports, manual bag emptying | 0.5 - 1.0 |

| fast | crusher, spraying booth, automatic sac/barrel filling | 1.5 - 2.5 |

| turbulent | grinding, sawing, polishing, sandblasting, trommel | up to 10.0 |

Another starting point for determining air volume is information on the design of pneumatic conveying equipment for bulk materials of all types.

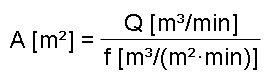

Determining the necessary filter area

As an initial approximation, the size of the filter required can be determined using the following equation:

Q = volume flow of gas passing through

A = filter area

f = specific fair-to-cloth ratio

| Particle characteristics | Effects on filtration performance |

| sticky-humid | good particle separation, bad dropping of filter cake |

| gut agglomerierend (großer Schüttwinkel), trocken | good particle separation, good dropping of filter cake |

| frei fließend (kleiner Schüttwinkel), trocken | bad particle separation, good dropping of filter cake |

Air-to-cloth ratio

The air-to-cloth ratio should be generally between 0.5 m³/(m² min) and 2.5 m³/(m² min). Common pressure drops of the filter media are between 400 Pa and 1,500 Pa. These ranges are determined, among others, by the following aspects:

- dust characteristics

- air-to-cloth ratio

- type of the filter media

- clean-gas dust content

- lifetime

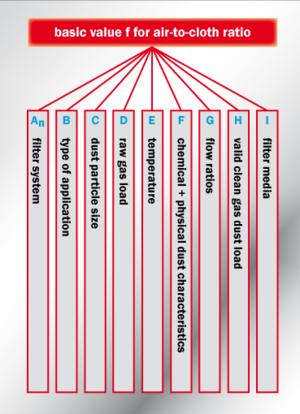

Parameters affecting the air-to-cloth ratio

Among others, the following aspects need to be considered to determine the air-to-cloth ratio:

- the raw-gas dust content

- the target clean-gas dust content

- the target system pressure drop

- the target service life of filter medium

- the gas composition (specifically the moisture content)

- the design of the separator /space requirements

- the cleaning type of the filter medium

The theoretical air-to-cloth ration feff is calculated then: = f ₓ An ₓ B ₓ C ₓ D ₓ E ₓ F ₓ G ₓ H ₓ I

Since each single parameter can are within a range of 0.45 to 1.5, there can be substantial differences to the basic value f. The influence is reduced with for e. g. a pocket filter AJN or bag filter and having uncritical process conditions.

In the simplest case, the factor can even be 1. The air-to-cloth ration feff can be halve compared to f in case of specific applicaitons with very fine dust and high temperature. therefore, please conatct a specialist in any case.

Source: Friedrich Löffler et al.: Staubabscheidung mit Schlauchfiltern und Taschenfiltern. Vieweg, 1984, S. 247.

Typical air-to-cloth ratio for filtration separators with compressed-air cleaning

| dust kinds / applications | air-to-cloth ratio m³/(m² min) with bag filter or pocket filter |

|---|---|

| iron oxides (kiln de-dusting in steel works) | 1 - 1.5 |

| fly ash from coal burning, handling | 1 - 1.5 |

| fly ash from coal burning, combustion depending on pre-separation and method of combustion | 0.5 - 1.5 |

| gypsum dust (burning of gypsum) | 1 - 1.6 |

| wood flour (grinding dust with content of glue) | 1.1 - 2.5 |

| sand conditioning of foundry molding sand | 1 - 2 |

| thermic spray process of aluminum | 0.5 - 0.6 |

| wheat grinding | 2.5 - 4.1 |

| zinc oxid dust (exhaust above zinc bath) | 1 - 1.5 |

| cement dust (transportation, loading) | 1.1 - 2 |

| sugar classification | 1.1 - 2 |

Specific air-to-cloth ratio

The specific face velocity f [m³/m²*min] affects the effectiveness and separation efficiency of the dust separator.

| Parameter | Specific air-to-cloth ratio (f) | |

|---|---|---|

| high | low | |

| Filter area | smaller | larger |

| Pressure loss | larger | smaller |

| Separation efficiency | worse | better |

| Abrasion | larger | smaller |

| Approaching flow | disadvantageous | advantageous |

| Space requirement | smaller | larger |

| Investment | smaller | higher |

| Operating / maintenance | expensive | less expensive |

Norm comparison filter classes for depth filter

Particulate air filters for general ventilation - according to DIN EN 779 (obsolete)

| Filter class | test dust / test aerosole | average arrestance (Am) compared with test dust in % | average efficiency (EM) of particle with 0,4 µm in % |

| G1 | ASHRAE dust | 50 < AM < 65 | |

| G2 | 65 < AM < 80 | ||

| G3 | 80 < AM < 90 | ||

| G4 | 90 < AM | ||

| M5 | DEHS 0,2 - 0,3 µm | 40 < EM < 65 | |

| M6 | 60 < EM < 80 | ||

| F7 | 80 < EM < 90 | ||

| F8 | 90 < EM < 95 | ||

| F9 | 95 < EM |

Particle for general ventilation - according to DIN EN ISO 16890

| Filter class | Coarse | ePM10 | ePM2,5 | ePM1 |

| G2 | 30 - 40 % | |||

| G3 | 45 - 65 % | |||

| G4 | 60 - 85 % | |||

| M5 | 50 - 60 % | |||

| M6 | 60 - 80 % | 50 - 60 % | ||

| F7 | 80 - 90 % | 65 - 75 % | 50 - 65 % | |

| F8 | 90 - 95 % | 75 - 95 % | 70 - 90 % | |

| F9 | 80 - 95 % |

Source: VDMA Luftfilterinformation

Norm comparison of remaining filter classes

high-efficiency particulate air filter (EPA, HEPA und ULPA) according to DIN EN 1822 (Teil 1 bis 5)

| filter class | test dust / test aerosole | integral collection efficiency in MPPS in % | Local separation grade in MPPS in % |

| E10 | DEHS (Di-Ethyl-Hexyl-Sebacat | > 85 | |

| E11 | > 95 | ||

| E12 | > 99,5 | ||

| H13 | > 99,95 | > 99,75 | |

| H14 | > 99,995 | > 99,975 | |

| U15 | > 99,9995 | > 99,9975 | |

| U16 | > 99,99995 | > 99,99975 | |

| U17 | > 99,999995 | > 99,999975 |

Filter materials for air filtration to recirculate in working spaces according to DIN EN 60335-2-69 annex AA

| filter class | dust class | test dust / test aerosole | maximum transmittance in % | appropriate for dry, für trockene, hazardous, non-flammable dusts |

| E10 | L | 200 mg/m3 quartz dust 90% 0,2-2 µm (Stokes) | < 1 | dusts with OEL > 1 mg/m3 |

| E11 | M | < 0,1 | dusts with OEL > 0,1 mg/m3 | |

| E12 | ||||

| H13 | H | 10-80 mg/m3 paraffin oil mist 90% < 1 µm (Stokes) | < 0,005 | dusts with OEL, carcinogenic aerosoles, dust with pathogenic agents |

| H14 | ||||

| U15 | ||||

| U16 | ||||

| U17 |

Source: VDMA Luftfilterinformation

OEL = Occupational exposure limit value